- Wärtsilä and Höegh Evi have introduced a floating ammonia-to-hydrogen cracker, revolutionizing sustainable energy transport.

- This innovation can store up to 120,000 cubic meters of ammonia, converting it into 210,000 tonnes of green hydrogen annually.

- The floating structures serve as both storage and regasification units, facilitating a global supply chain for green hydrogen.

- This technology aims to reduce the carbon footprint and support Europe’s industrial energy demands sustainably.

- Wärtsilä and Höegh Evi’s project represents progress through daring innovation, aligning ecological goals with economic benefits.

- The project not only symbolizes technological advancement but also paves the way for a cleaner, greener future.

In the relentless pursuit of sustainable energy solutions, two visionary firms have set a new benchmark for innovation. Finnish technology leader Wärtsilä and Norwegian energy pioneer Höegh Evi have collaboratively sparked a revolution in energy transport with their latest brainchild: a floating ammonia-to-hydrogen cracker that promises a greener future.

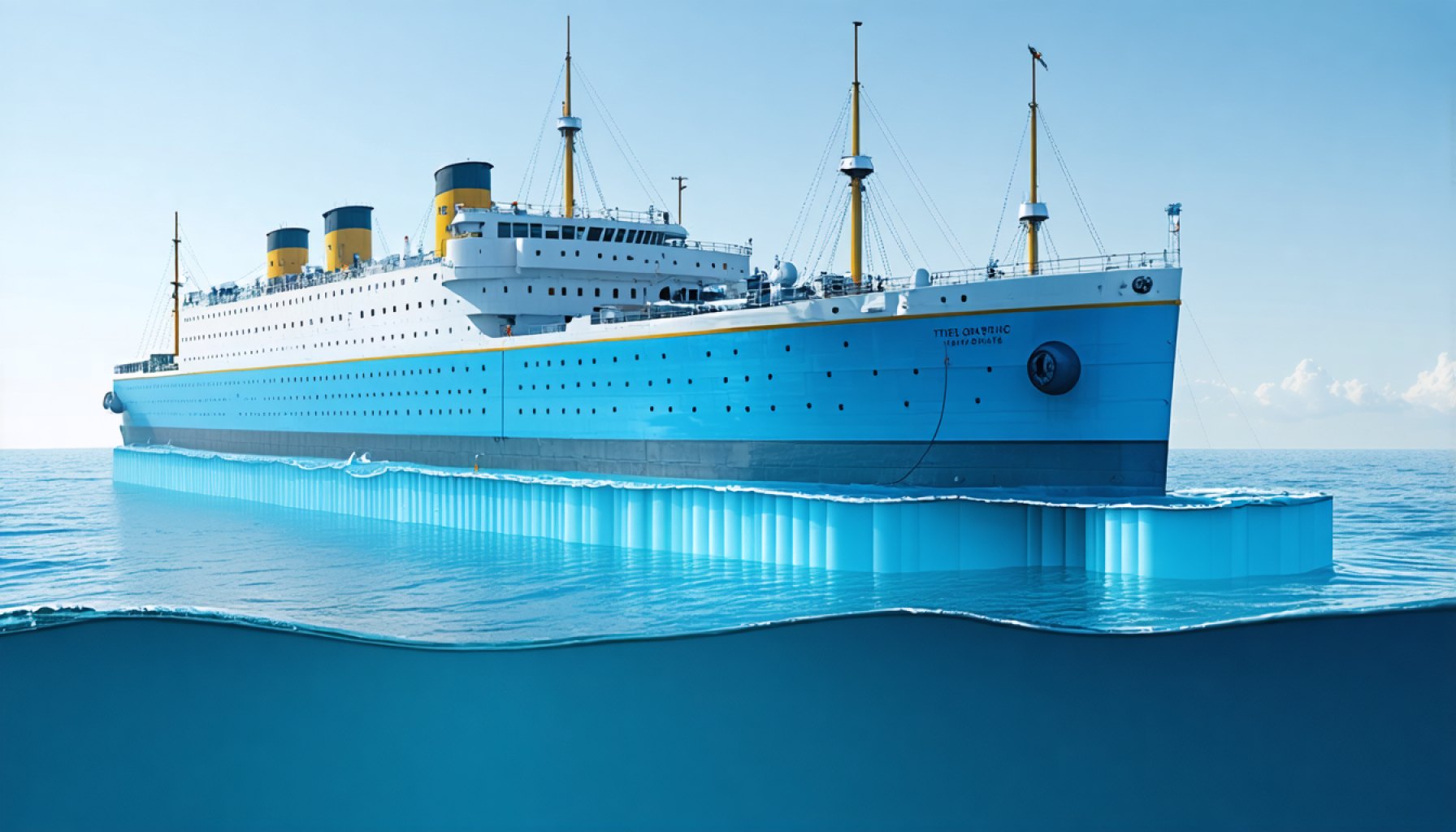

Picture this: a vast, shimmering vessel anchored on the open sea, its structure a beacon of ingenuity. This modular marvel is capable of storing an oceanic volume of up to 120,000 cubic meters of ammonia, waiting to be transformed into a staggering 210,000 tonnes of the most clean-burning fuel known to humankind each year. The potential of this innovation is as expansive as the oceans it adorns.

These floating giants don’t just blend into the maritime scenery; they transform it. The beauty of this design lies in its ability to be both a floating storage unit and a sophisticated regasification facility, adapting seamlessly to the energy needs of today while anticipating the demands of tomorrow. Bridging continents, these floating terminals pave a liquid highway for green hydrogen, connecting global supply chains straight to the industrial heartlands of Europe.

But this is about more than just technology. It is about igniting a movement towards a brighter, cleaner world. As the winds of change steer us away from fossil fuels, this floating innovation could well be the torchbearer, illuminating the path for an entire industry. By harnessing the strengths of both ammonia and hydrogen, these floating crackers promise not only to meet the demands of modern energy consumption but to do so with an eye on environmental responsibility.

Consider the implications: a consistent, reliable stream of green energy fueling European industry, reducing the carbon footprint, and transforming energy infrastructures. The message is clear—innovation is not just about creating something new; it’s about unlocking potential across boundaries, aligning ecological harmony with economic prowess.

As this floating dream inches closer to full-scale reality, it delivers a powerful takeaway: True progress lies in daring now, in envisioning the seemingly impossible, and in building pathways where none existed before. Wärtsilä and Höegh Evi have done just that, weaving a narrative of hope on the high seas—a testament to the limitless possibilities when technology and ambition sail together.

Revolutionizing Renewable Energy: The Floating Ammonia-to-Hydrogen Approach

The latest collaboration between Wärtsilä and Höegh Evi has the potential to redefine the landscape of renewable energy with their innovative floating ammonia-to-hydrogen cracker. These floating terminals not only represent the pinnacle of maritime engineering but also the promise of a sustainable energy future. Below, we delve into various facets of this groundbreaking project and explore its broader implications for the energy sector.

Understanding the Technology Behind Floating Cracking Units

1. Mechanism of Action: These floating units operate by converting stored ammonia into hydrogen via a cracking process. Ammonia is advantageous due to its higher energy density compared to pure hydrogen and its easier storage and transport. Once at the destination, ammonia is cracked to release hydrogen, which could then be used as a clean fuel source across various sectors.

2. Environmental Impact: Utilizing ammonia as an energy carrier reduces the need for complex and expensive hydrogen transportation infrastructure. Ammonia can be liquefied and transported under relatively mild conditions compared to hydrogen, which typically requires cryogenic temperatures.

3. Scalability and Adaptability: The modular design allows these platforms to scale according to demand and geographical needs. This adaptability positions them as versatile solutions supporting a wide range of industrial applications from shipping to electricity generation.

Industry Implications and Market Trends

1. Global Hydrogen Economy: According to the International Energy Agency (IEA), hydrogen demand could reach up to 500 million tonnes by 2050. The infrastructure created by floating ammonia-to-hydrogen converters could support this burgeoning global hydrogen economy, boosting production efficiencies and reducing logistical barriers.

2. Environmental Regulations: As global efforts intensify to reduce carbon emissions, technologies like these are likely to benefit from supportive policies and incentives designed to encourage low-carbon energy solutions.

3. Market Forecast: Analysts observe an anticipated CAGR of over 8% in the hydrogen generation market through 2030, driven primarily by the expanding adoption of green hydrogen. Floating units may capture a significant share of this growth by addressing some logistical challenges in hydrogen transport and storage.

Pros and Cons Overview

Pros:

– Reduces Carbon Footprint: Significantly lower emissions compared to fossil fuels.

– Efficient Use of Renewable Energy: Converts renewables into storable ammonia, which can be cracked back into hydrogen.

– Versatility and Scalability: Easily tailored to meet different energy demands.

Cons:

– Infrastructure Development: Needs initial investment in ammonia production.

– Technological Challenges: Requires cutting-edge technology for efficient conversion processes.

– Regulatory Hurdles: Navigating through international regulations for ammonia and hydrogen transport might delay implementation.

Controversies and Limitations

Safety Concerns: Handling ammonia involves risks due to its toxicity and corrosive nature. Safety protocols and robust protective measures are critical during transportation and cracker operation.

Economic Viability: While the concept is technologically innovative, its economic feasibility depends significantly on advancements in ammonia and hydrogen production and continuously evolving energy markets.

Actionable Recommendations

1. Investment in Research: Stakeholders should continue investments in R&D to overcome technical and safety challenges associated with ammonia cracking and hydrogen production.

2. Engagement with Policy Makers: Engaging with governments to craft favorable regulations could enhance scalability and adoption rates.

3. Public-Private Partnerships: Collaborations between governments, private firms, and research institutions could accelerate technological developments and deployment.

Conclusion

The floating ammonia-to-hydrogen cracker developed by Wärtsilä and Höegh Evi stands as a pioneering beacon in the shift toward sustainable energy. By transforming the way we store and transport hydrogen, these platforms could offer a pathway to significantly reduce global carbon emissions. By addressing the challenges and leveraging the opportunities presented by this innovation, stakeholders can harness the full potential of this transformative technology.

For more on Wärtsilä’s maritime and energy solutions, visit Wärtsilä. Discover more about renewable energy advancements at Höegh.